K614 : Buffer Seals

Material

|

Material

|

|

Polyurethane HPU82 shore + back up Poly acetal anti-extrusion

|

|

Polyurethane HPU95A + back up Poly acetal anti-extrusion

|

Introduction

K614 is a rod buffer seal. It provides the designer with a compact low friction seal for light to medium duty hydraulic cylinders.

This compact rod/gland seal provides optimum sealing performance combined with smooth operation and low levels of breakout and dynamic friction.

It is designed to provide a action valve to prevent excessive pressure build up in the cavity between buffer seals and the rod seal. It used to act as a buffer seal for the primary rod sea. K614 profile provides the majority of the rod sealing performance while allowing fluid to the by pass and energize the primary rod seal. Fluid located between The K614 profile and rod seal will relieve back into the cylinder by flowing past.

It has a special combined Polyurethane HPU82 shore with Polyacetal anti-extrusion The U - Cup is designed to have a contact area with the rod adequate to retain the media at low pressure. As high pressure acts on the O ring it compresses the lip against the rod increasing the contact area and the effectiveness of the seal.

Energizer

Standard material: Polyurethane HPU82

Special materials: other elastomers to suit operating conditions, including fluoroelastomer (FKM) for high

temperature duties.

Back up

Standard material: Polyacetal anti-extrusion.

Special materials: PTFE + 46% bronze.

Ø High performance single-acting seal providing low wear and maintenance.

Ø Low dynamic and breakout friction for instant response, smooth operation and reduced power consumption.

Ø Rectangular energizer stabilizes sealing element during operation giving optimum fluid retention and seal life.

Typical applications

Systems where instant response and low power consumption are important and leakage is unacceptable.

Examples include: hydraulic cylinders, mobile hydraulics, injection moulding machines, and down stroking presses.

Standard seals are supplied with a nitrile O ring but other materials can be provided.

This pressure relief feature allows the K614 profile to be used in tandem or multiple seal arrangements. The K614 features low friction, long life, and versatility.The compression force is spread out over a larger area allowing trapped fluid to pass under the seal and return to the system.

The K614 profile is a rod seal that can be used as a buffer seal in conjunction with a primary rod seal or in tandem with itself to form a sealing system for higher performance. The K614 profile is a unidirectional seal, with a unique design that allows trapped fluid pressure back into the cylinder. When the rod extends from the cylinder the K614 profile is riding on a sealing point, creating a high compression point to limit leakage. As the rod goes through its return stroke this seal rocks forward, creating a larger sealing surface on the rod.

|

Material

|

Power-transmission fluid

|

Temperature ⁰C

|

Speed

|

Pressure

|

Max. Gap F

|

|

PU + POM Acetal

|

Mineral Oil (NBR)

|

-30 - +110

|

≤ 15m/s

|

160 bar

|

F ≤ 0,6 mm

|

|

Mineral Oil (FKM)

|

-30 - +220

|

|

250 bar

|

F ≤ 0,4 mm

|

|

|

|

400 bar

|

F ≤ 0,3 mm

|

|

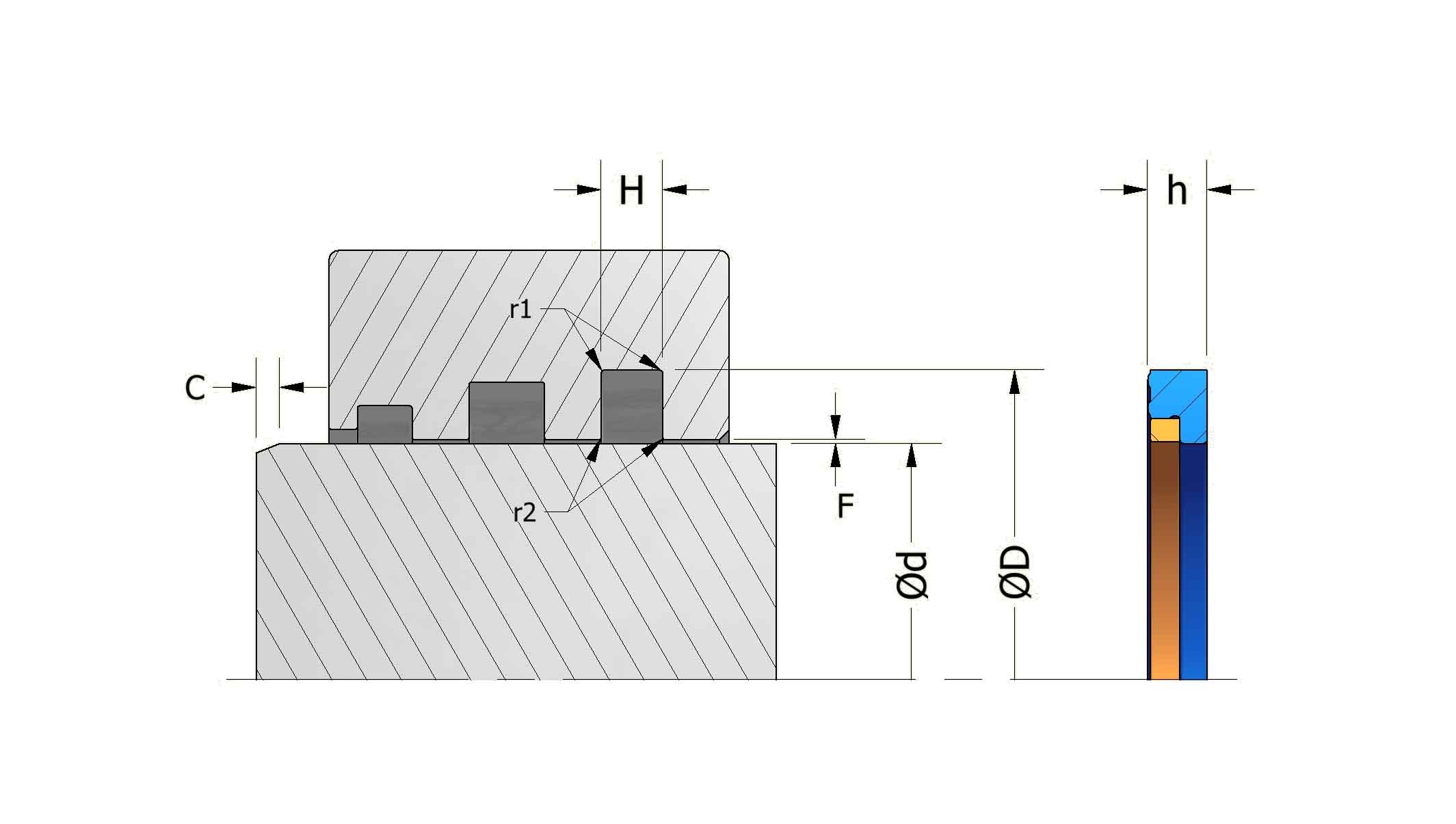

Chamfers & Rad

|

Tolerance

|

Surface Finishing

|

|

(mm)

|

µm Ra

|

µm Rt

|

|

S ≤

|

3.75

|

5.5

|

7.5

|

10.5

|

12.5

|

15

|

ø d

|

f8 / h9

|

0,1-0,4

|

≤ 4

|

|

C ≥

|

2

|

3

|

5

|

7.5

|

8

|

8.5

|

ø D

|

H9

|

≤ 1,6

|

≤ 10

|

|

r1 ≤

|

0.4

|

0.8

|

1.2

|

1.6

|

1.6

|

2.0

|

L

|

+0,2 -0

|

≤ 3,2

|

≤ 16

|

Dimension

|

Model

|

d

|

Tolerance

f8/h9

|

D

|

Tolerance

H9

|

H

|

L +0.2

0

|

|

K614

|

4

|

-0.010

-0.028

|

8.9

|

+0.036

+0.00

|

2

|

2.2

|

|

K614

|

5

|

-0.010

-0.028

|

9.9

|

+0.036

+0.00

|

2

|

2.2

|

|

K614

|

6

|

-0.013

-0.035

|

10.9

|

+0.043

+0.00

|

2

|

2.2

|

|

K614

|

7

|

-0.013

-0.035

|

11.9

|

+0.043

+0.00

|

2

|

2.2

|

|

K614

|

8

|

-0.013

-0.035

|

12.9

|

+0.043

+0.00

|

2

|

2.2

|

|

K614

|

8

|

-0.013

-0.035

|

15.3

|

+0.043

+0.00

|

2.9

|

3.2

|

|

K614

|

10

|

-0.016

-0.043

|

14.9

|

+0.043

+0.00

|

2

|

2.2

|

|

K614

|

10

|

-0.016

-0.043

|

17.3

|

+0.043

+0.00

|

2.9

|

3.2

|

|

K614

|

12

|

-0.016

-0.043

|

16.9

|

+0.043

+0.00

|

2

|

2.2

|

|

K614

|

12

|

-0.016

-0.043

|

19.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

14

|

-0.016

-0.043

|

18.9

|

+0.052

+0.00

|

2

|

2.2

|

|

K614

|

14

|

-0.016

-0.043

|

21.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

15

|

-0.016

-0.043

|

19.9

|

+0.052

+0.00

|

2

|

2.2

|

|

K614

|

15

|

-0.016

-0.043

|

22.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

16

|

-0.016

-0.043

|

20.9

|

+0.052

+0.00

|

2

|

2.2

|

|

K614

|

16

|

-0.016

-0.043

|

23.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

18

|

-0.020

-0.053

|

22.9

|

+0.052

+0.00

|

2

|

2.2

|

|

K614

|

18

|

-0.020

-0.053

|

25.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

20

|

-0.020

-0.053

|

27.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

20

|

-0.020

-0.053

|

30.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

22

|

-0.020

-0.053

|

29.3

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

22

|

-0.020

-0.053

|

32.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

22.4

|

-0.020

-0.053

|

29.7

|

+0.052

+0.00

|

2.9

|

3.2

|

|

K614

|

22.4

|

-0.020

-0.053

|

33.1

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

25

|

-0.020

-0.053

|

32.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

25

|

-0.020

-0.053

|

35.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

28

|

-0.020

-0.053

|

35.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

28

|

-0.020

-0.053

|

38.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

30

|

-0.025

-0.064

|

37.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

30

|

-0.025

-0.064

|

40.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

32

|

-0.025

-0.064

|

39.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

32

|

-0.025

-0.064

|

42.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

35

|

-0.025

-0.064

|

42.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

35

|

-0.025

-0.064

|

45.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

35.5

|

-0.025

-0.064

|

42.8

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

35.5

|

-0.025

-0.064

|

46.2

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

36

|

-0.025

-0.064

|

43.3

|

+0.062

+0.00

|

2.9

|

3.2

|

|

K614

|

36

|

-0.025

-0.064

|

46.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

38

|

-0.025

-0.064

|

48.7

|

+0.062

+0.00

|

3.9

|

4.2

|

|

K614

|

38

|

-0.025

-0.064

|

53.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

40

|

-0.025

-0.064

|

50.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

40

|

-0.025

-0.064

|

55.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

42

|

-0.025

-0.064

|

52.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

42

|

-0.025

-0.064

|

57.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

45

|

-0.025

-0.064

|

55.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

45

|

-0.025

-0.064

|

60.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

50

|

-0.030

-0.076

|

60.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

50

|

-0.030

-0.076

|

65.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

56

|

-0.030

-0.076

|

66.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

56

|

-0.030

-0.076

|

71.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

60

|

-0.030

-0.076

|

70.7

|

+0.074

+0.00

|

3.9

|

4.2

|

|

K614

|

60

|

-0.030

-0.076

|

75.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

63

|

-0.030

-0.076

|

78.1

|

+0.074

+0.00

|

5.9

|

6.3

|

|

K614

|

65

|

-0.030

-0.076

|

80.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

67

|

-0.030

-0.076

|

82.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

70

|

-0.030

-0.076

|

85.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

71

|

-0.030

-0.076

|

86.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

75

|

-0.030

-0.076

|

90.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

80

|

-0.036

-0.090

|

95.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

85

|

-0.036

-0.090

|

100.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

90

|

-0.036

-0.090

|

105.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

95

|

-0.036

-0.090

|

110.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

100

|

-0.036

-0.090

|

115.1

|

+0.087

+0.00

|

5.9

|

6.3

|

|

K614

|

105

|

-0.036

-0.090

|

120.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

110

|

-0.036

-0.090

|

125.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

112

|

-0.036

-0.090

|

127.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

115

|

-0.036

-0.090

|

130.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

120

|

-0.043

-0.106

|

135.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

125

|

-0.043

-0.106

|

140.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

130

|

-0.043

-0.106

|

145.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

135

|

-0.043

-0.106

|

150.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

140

|

-0.043

-0.106

|

155.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

150

|

-0.043

-0.106

|

165.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

160

|

-0.043

-0.106

|

175.1

|

+0.100

+0.00

|

5.9

|

6.3

|

|

K614

|

170

|

-0.043

-0.106

|

185.1

|

+0.115

+0.00

|

5.9

|

6.3

|

|

K614

|

180

|

-0.050

-0.122

|

195.1

|

+0.115

+0.00

|

5.9

|

6.3

|